Welcome to DST-IITH ICMAP for Bioenergy and Hydrogen

Inaugurated by

Dr. Jitendra singh

Hon'ble Minister of State Science & Technology and Hon'ble Minister of State Earth Sciences

04th April 2022

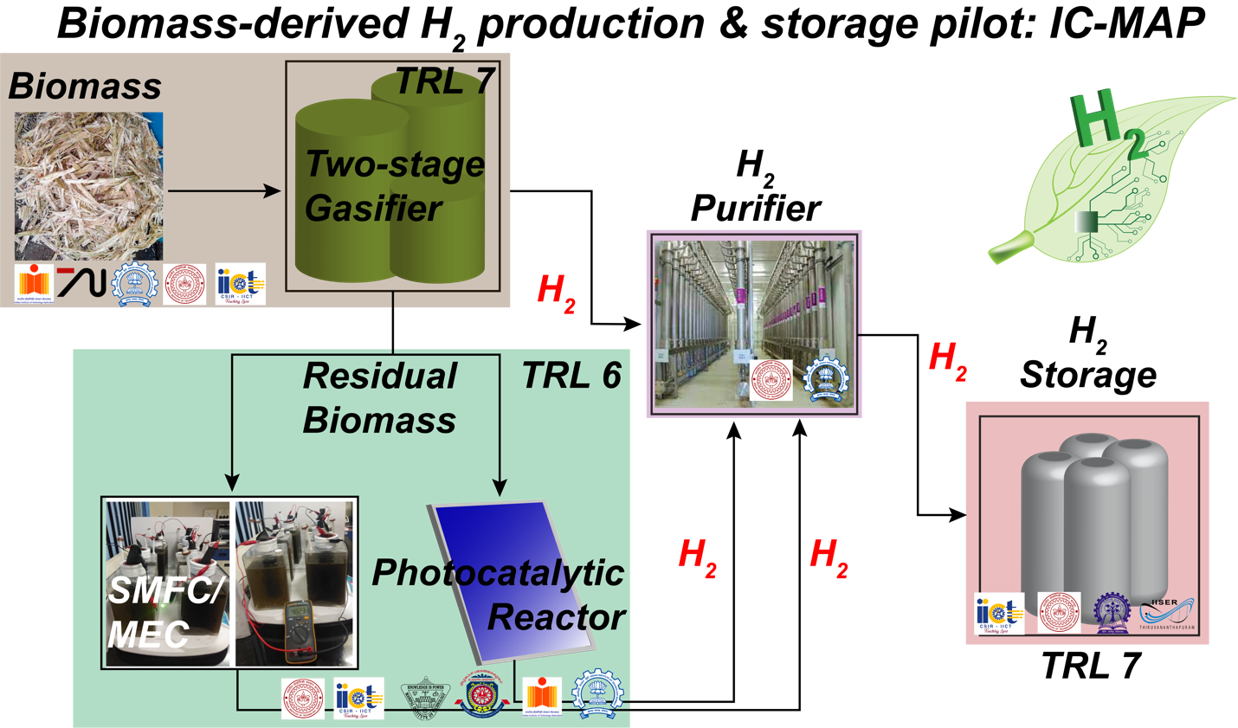

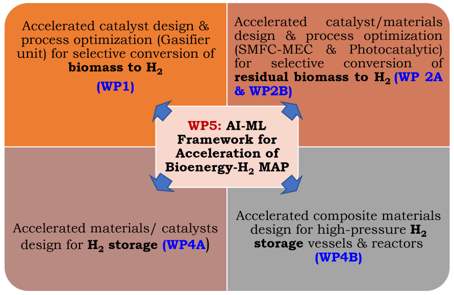

DST-IIT Hyderabad Integrated Clean Energy Material Acceleration Platform on Bioenergy and Hydrogen

A consortium on Green Hydrogen: Evolution to Revolution

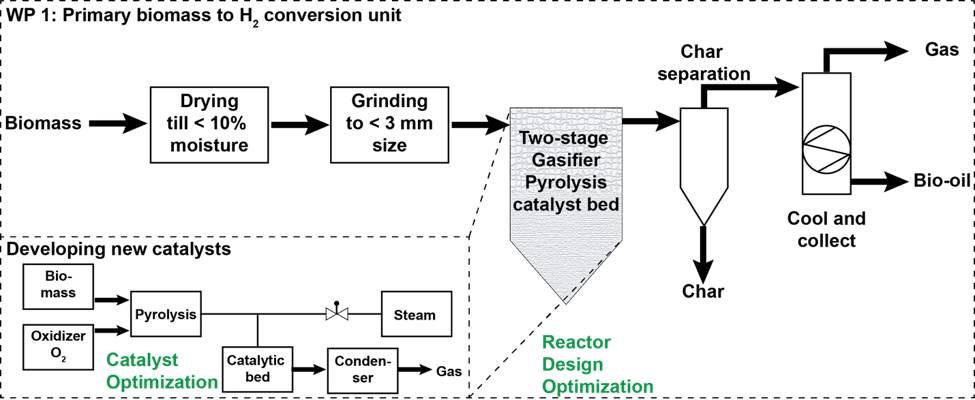

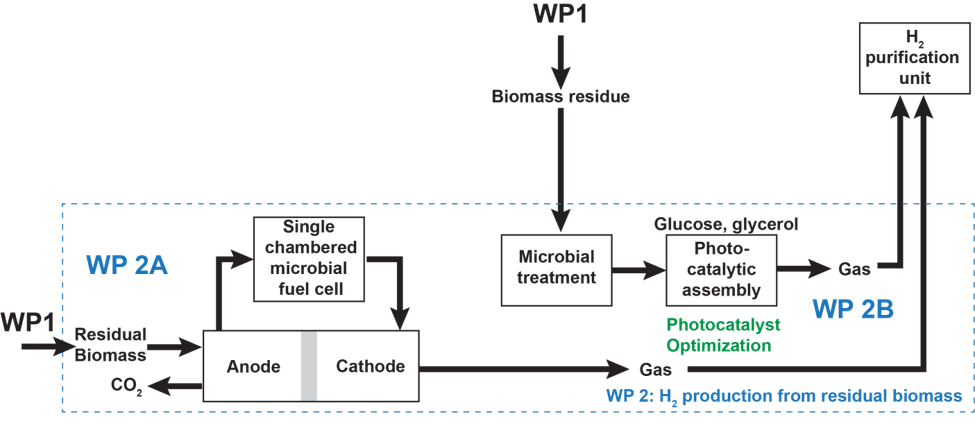

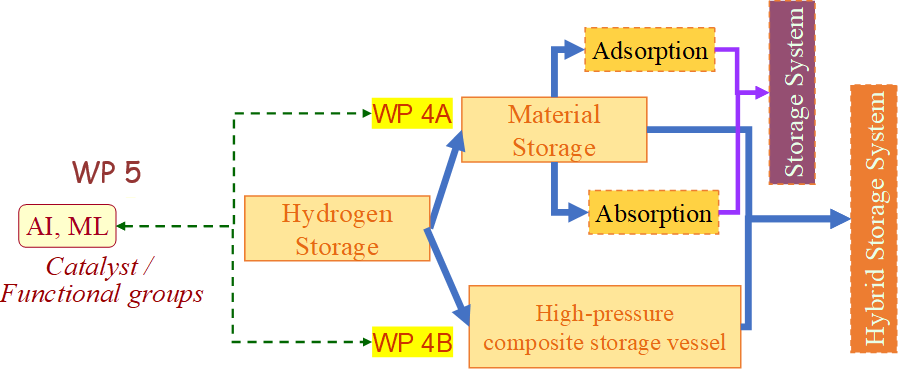

A collaborative AI/ML enabled accelerated technology development platform for sustainable hydrogen generation and storage from waste biomass